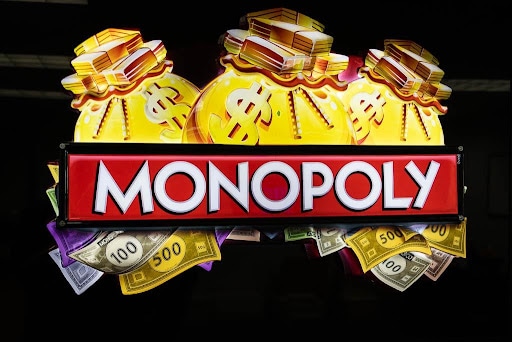

Distortion forming gets its name from the artwork being distorted prior to thermoforming. This is the unique process of printing an image, logo or similar item on plastic with formable grade inks then thermoforming the sheet to create a dynamic 3-dimensional shape. Many times, these images and signs are backlit to create a highly impactful effect.

Custom Distortion Digital Printing, Thermoforming Services

Projects:

- Custom Injection Molded ABS Plastic Armrest for Riding Mowers

- Custom Injection Molded Nylon Plastic Cap for Commercial Vehicles

- Custom Plastic Injection Molded ABS Bin for Food Service Machinery

- Plastic Thermoformed High Impact Polystyrene Front Fascia for the Gaming Industry

- Plastic Thermoformed Parts Tray for Food Service Machinery

- Custom Distortion Digital Printing, Thermoforming Services

Distortion Thermoforming Services Capabilities:

| Molding Process |

|

|

|---|---|---|

| Material |

|

|

| Colors |

|

|

| Additional Services |

|

|

| Maximum Length |

|

|

| Maximum Width |

|

|

| Thickness (Base Material) |

|

|

| Molding Weight |

|

|

| Number of Cavities |

|

|

| Tolerance (+/-) |

|

|

| Industry Focus |

|

|

| Associations |

|

|

| Lead Time |

|

|

| Production Volume |

|

|

| Efficiency |

|

|

| File Formats |

|

|

Associations & Certifications