Custom Distortion Digital Printing, Thermoforming Services

Northern Precision Plastics has the distinction of being one of the best distortion thermoforming companies in the United States. Distortion thermoforming is the process of taking printed plastic sheet and vacuum forming the image or picture over the thermoformed mold. The printed image is then displayed or distorted over the part resulting in unbelievable finished parts. The colors and images that can be formed are unlimited. The process allows the parts to be back lighted resulting in even more possible image combinations.

Northern Precision Plastics has the distinction of being one of the best distortion thermoforming companies in the United States. Distortion thermoforming is the process of taking printed plastic sheet and vacuum forming the image or picture over the thermoformed mold. The printed image is then displayed or distorted over the part resulting in unbelievable finished parts. The colors and images that can be formed are unlimited. The process allows the parts to be back lighted resulting in even more possible image combinations.

With the addition of digital printing we have full control of the image to make any adjustments in a matter of minutes.

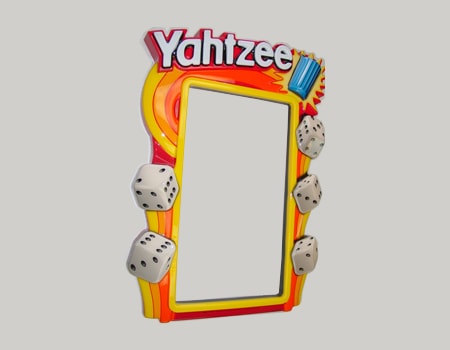

We work with the best plastic materials available and partner with your company to take your ideas and make them a reality. We can even show you in 3D what the part will look like before we mold any images. In the photo you will notice how the blue cup is formed over the raised cup, the dice are formed over raised dice images, and even more amazing the letters are formed in white over the raised letters with no bleeding of the colors on the adjacent surfaces. We are very professional on how we create these parts and will meet or exceed your standards and expectations. Give us a call or contact us today.

Projects:

- Custom Injection Molded ABS Plastic Armrest for Riding Mowers

- Custom Injection Molded Nylon Plastic Cap for Commercial Vehicles

- Custom Plastic Injection Molded ABS Bin for Food Service Machinery

- Plastic Thermoformed High Impact Polystyrene Front Fascia for the Gaming Industry

- Plastic Thermoformed Parts Tray for Food Service Machinery

- Custom Distortion Digital Printing, Thermoforming Services

Distortion Thermoforming Services Capabilities:

| Molding Process |

|

|

|---|---|---|

| Material |

|

|

| Colors |

|

|

| Additional Services |

|

|

| Maximum Length |

|

|

| Maximum Width |

|

|

| Thickness (Base Material) |

|

|

| Molding Weight |

|

|

| Number of Cavities |

|

|

| Tolerance (+/-) |

|

|

| Industry Focus |

|

|

| Associations |

|

|

| Lead Time |

|

|

| Production Volume |

|

|

| Efficiency |

|

|

| File Formats |

|

|

Associations & Certifications